Matte sab kho cov khoom lag luam qis

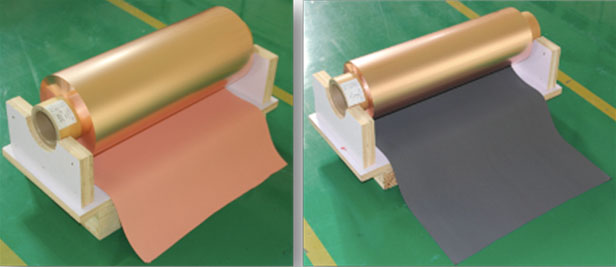

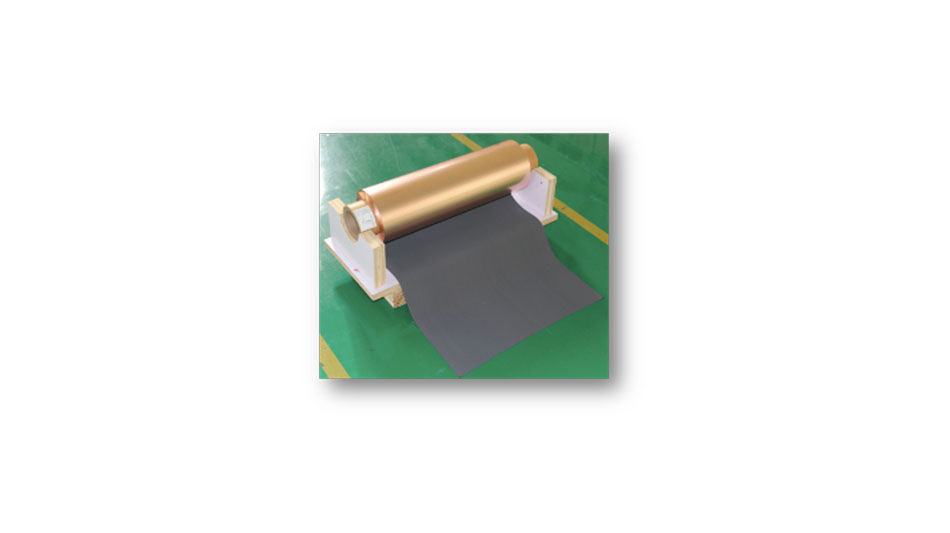

Kho cov profiles dov tooj liab ntawv ci nrog dub / liab matte sab

Dov Tooj Liab Ntawv Nyiaj Cwj Pwm

Thaum lub sij hawm downstream cua sov txheej txheem, cov khoom yuav dhau ib qho kev hloov pauv ntawm ib nrab ntawm LED

●Tus Kho Siab Cig Tooj Ntawv Nyiaj Tooj Ntawv Nrog Liab Matte Sab

●Cov tshuaj kho kom nrov tooj liab ntawv ci nrog sab dub matte

●Thickness: 9um 12um 18um 22um 35um 50um 70um

●Dav: 250 ~ 630 hli, qauv dav: 520mm, tuaj yeem txiav li kev thov

●Ntoo lub thawv pob

●Cov khoom lag luam yog nce mus rau ROHS ib puag ncig cov qauv

●ID: 76 hli

●Ntev: Mekas

●Qauv tuaj yeem muab kev txhawb nqa

●Dov Ntev Ib Tug Tseem Ceeb: Raws li ib qho kev thov

●Yob sab hauv lub taub thiab txheej hla: raws li kev thov

●Tsawg roughness

●Siab yooj yim

●Zoo heev etching kev ua tau zoo

●Kho cov ntawv ci hauv cov xim dub lossis xim liab

●Blackened ntawv ci muaj siab hloov, qis nto roughness thiab lub cev thiab tshuaj lom neeg.

●Thov rau FPC (Saj zawg zog cov ntawv tshaj tawm) Siv cov teb: Cov ntaub ntawv sau thiab cov kws tshaj lij; Cov khoom lag luam ntau dua xws li aerospace, cov khoom siv kho mob, cov twj, kev sib txuas lus, cov khoos phis tawj thiab cov khoom siv tsheb kho tsheb.

●Thov rau FCCL / hloov pauv hloov pauv tooj liab

●Thov kom yoog raws kev sib txuas tau, siab kawg hloov tau LED thiab saj lub xov tooj ntawm tes xov tooj ntawm tes thiab lwm daim teb siab

●Saj zawg zog cov ntawv tshaj tawm

| Kev sib faib | Ib yam | Txoj kev xeem | ||||||||||||||

| Nominal tuab | Um | 9 | 12 | 18um | 35UM | 22um | 50UM | 70UM | Txoj kev xeem | |||||||

| Thaj chaw hnyav | g / m² | 80 ± 2 | 107 ± 3 | 160 ± 4 | 311 ± 5 | 196 ± 4 | 445 ± 5 | 623 ± 5 | GB / T29847-2013 | |||||||

| Kev coj dawb huv | % | Min.99.97 | GB / T5121 | |||||||||||||

| Nto roughness | Ci iab sab (RA) | Um | Max.0.2 | GB / T29847-2013 | ||||||||||||

| Matte sab (rz) | Um | 0.8-1.2 | ||||||||||||||

| Lub zog tensile | Rm li | N / mm² | ≥370 | ≥370 | ≥370 | ≥370 | ≥370 | ≥370 | ≥370 | GB / T29847-2013 | ||||||

|

|

|

|

|

| ||||||||||||

| RM 180 ° C * 30MIN. | ≥160 | ≥160 | ≥160 | ≥170 | ≥170 | ≥170 | ≥170 | |||||||||

| Elongation | Zoo li ib txwm | % | ≥1.0 | ≥1.0 | ≥1.0 | ≥1.0 | ≥1.0 | ≥1.0 | 1≥1.0 | GB / T29847-2013 | ||||||

| 180 ° C * 30min | ≥7 | ≥7 | ≥8 | ≥11 | ≥9 | ≥13 | ≥20 | |||||||||

| Tev lub zog | N / hli | ≥0.8 | ≥0.8 | ≥1.0 | ≥1.2 | ≥1.0 | 4 | ≥2.0 | GB / T29847-2013 | |||||||

| Nto Zoo | / | Cov xim tsis zoo nkauj,Tsis muaj wrinkle,Tsis muaj khawb,Tsis muaj qhov pit thiab salient point | ||||||||||||||

| Tshuaj Kuj | % | Max.5 | ||||||||||||||

| Oxidation tsis kam | 200 ° C / 60min | Tsis-discoloring | Q / Tobjb004-2015 | |||||||||||||

| Solder tiv thaiv |

| 300 ° C / 20s tsis muaj hlwv | ||||||||||||||

Cov khoom lag luam yog nce mus rau ROHS Environmental tus qauv.

Kho cov profiles dov tooj liab ntawv ci nrog balck / red iage