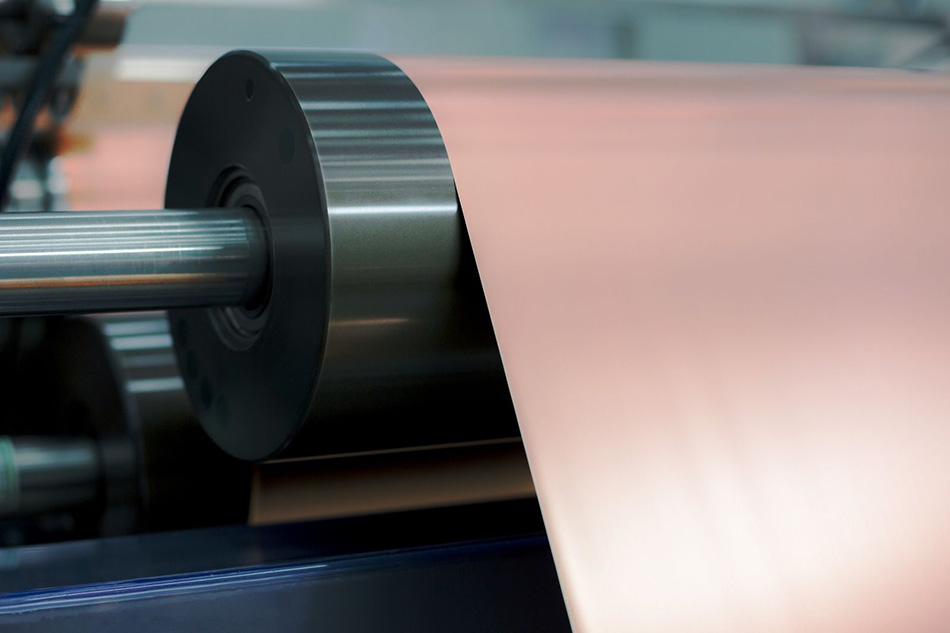

Tsawg Profile tooj liab ntawv ci (LP -SP / B)

●Thickness: 12um 18um 2530um 50um 70um 105um

●Txheem Dav: 1290mm, tuaj yeem txiav ua qhov loj me

●Ntoo lub thawv pob

●ID: 76 hli, 152 hli

●Ntev: Mekas

●Qauv tuaj yeem muab tau

Cov ntawv ci no yog siv rau multilayered pcbs thiab high-density Circuit Cours, uas yuav tsum tau ua kom zoo dua li ntawm tooj liab lub suab ntawv yog li ua yeeb yam xws li chaning tsis muaj peev xwm tuaj yeem nyob ntawm theem siab. Nws zwm rau cov qeb tshwj xeeb ntawm electrolytic tooj liab ntawv nyiaj nrog kev tswj roughness. Piv nrog tsis tu ncua electrolytic tooj liab ntawv ci, lub muaju ntawm lp tooj liab ntawv yog heev zoo heev nplua mias (<2 / zm). Lawv muaj Lamellar Crystals es tsis muaj cont contections, thaum lawv muaj cov kab tiaj tiaj thiab theem qis ntawm qhov chaw muaj sia. Lawv muaj cov kev cog lus zoo li zoo dua qhov loj dua ruaj khov thiab siab dua.

●Tsawg profile rau FCCL

●Siab mit

●Zoo heev etchability

●Kho cov ntawv ci yog xim liab lossis xim dub

●3layer fccl

●EMI

| Kev sib faib | Ib yam | Qhov toob kas | Txoj kev xeem | ||||||||

| Nominal tuab | Um | 12 | 18 | 25 | 35 | 50 | 70 | 105 | IPC-4562A | ||

| Thaj chaw hnyav | g / m² | 107 ± 5 | 153 ± 7 | 225 ± 8 | 285 ± 10 | 435 ± 15 | 585 ± 20 | 870 ± 30 | IPC-TM-650 2.2.12.2 | ||

| Kev coj dawb huv | % | ≥99.8 | IPC-TM-650 2.3.15 | ||||||||

| kev ntxhib | Ci iab sab (RA) | ս m | I≤0.43 | IPC-TM-650 2.3.17 | |||||||

| Matte sab (rz) | um | ≤4.5 | 50.0 | The≤6.0 | 5 xyoos.0 | ≤8.0 | PC12 | ≤14 | |||

| Lub zog tensile | RT (23 ° C) | MPa | ≥207 | ≥276 | IPC-TM-650 2.4.18 | ||||||

| Ht (180 ° C) | ≥138 | ||||||||||

| Elongation | RT (23 ° C) | % | ≥4 | ≥4 | ≥5 | ≥8 | ≥10 | ≥12 | ≥12 | IPC-TM-650 2.4.18 | |

| Ht (180 ° C | ≥4 | ≥4 | ≥5 | ≥6 | ≥8 | ≥8 | ≥8 | ||||

| Rqhov tseem ceeb | Ω.g / m² | I≤0.17 0 | I≤0.1 66 |

| I≤0.16 2 |

| I≤0.16 2 | I≤0.16 2 | IPC-TM-650 2.5.14 | ||

| Tev lub zog (FR-4) | N / hli | ≥1.0 | ≥1.3 |

| ≥1.6 |

| ≥1.6 | *.1 | IPC-TM-650 2.4.8 | ||

| Pinholes & Porosos | Tus nab npawj |

|

| No | IPC-TM-650 2.1.2 | ||||||

| Los tiv thaiv-oxidization | RT (23 ° C) | Dnyob hoom |

|

| 180 | ||||||

| Ht (200 ° C) | Feeb |

|

| 30 | |||||||

Txheem dav, 1295 (± 1) hli, thaj tsam dav: 200-1340mm. Thov raws li cov neeg siv khoom thov txiav.