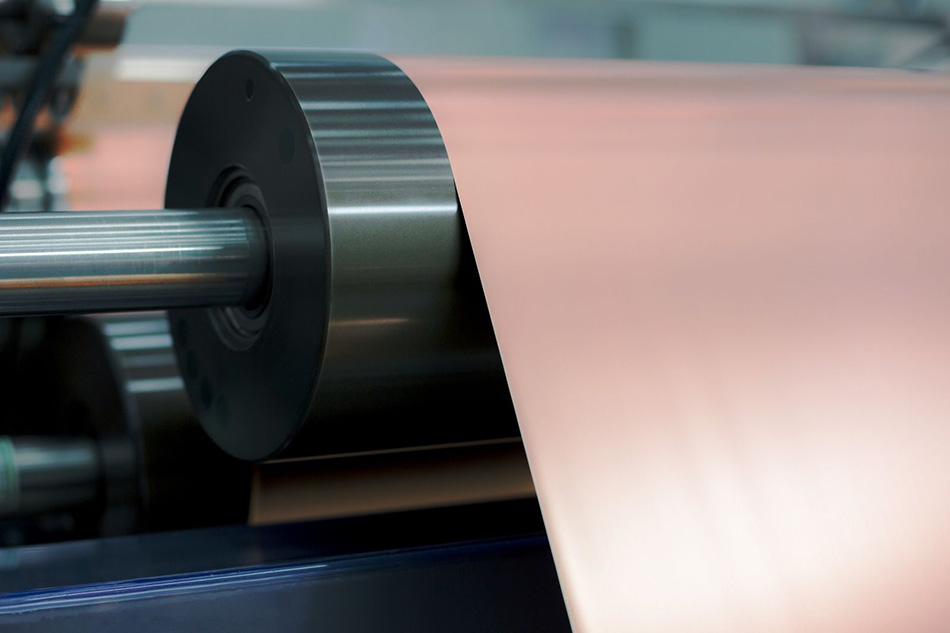

Hote Kub elongation tooj liab ntawv nyiaj

●Thickness: 12um 15um 18um 35um 70um 105um

●Txheem Dav: 1290mm, tuaj yeem txiav ua qhov loj me

●Ntoo lub thawv pob

●Qhov zoo yog raws GB / T5230-1995 thiab IPC-4562Tiv

●ID: 76 hli, 152 hli

●Ntev: Mekas

●Qauv tuaj yeem muab tau

Lub tuam txhab tau tsim zoo-nplej thiab cov zog-zog tooj liab ntawv los kub thiab qhov kub-kub ua tau zoo. Cov ntawv ci nta avory zoo nplej thiab siab tsis muaj zog thiab tuaj yeem tiv thaiv cov roj ntsha, yog li haum rau sab hauv thiab sab nraud txheej ntawm ib qho chaw zov me nyuam. Nrog qib qis ntawm qhov chaw nyob ntawm qhov chaw thiab zoo heev etchability, nws siv tau rau qhov ntom ntom ntom thiab thinness. Nrog lub zog tensile zoo heev, nws pab txhim kho kev hloov pauv tau zoo thiab yog feem ntau thov hauv pultilayer pcb zoo li lub phaj nyeem. Nrog rau kev txhawb nqa zoo heev thiab tawv, nws tsis yooj yim nraus rau ntug lossis quav, txhim kho cov khoom lag luam conformance tus nqi.

●Kho cov ntawv ci hauv grey lossis liab

●High Vwj Zog

●Zoo etchability

●Zoo heev corrosion

●Anti ntawv ci cracking los ntawm siab elongation ntawm siab kub

●Siab elongation tom qab kho nrog kub lossis annealing.

●Siab cov cuab yeej.

●Ua tau zoo nyob rau hauv kev tiv thaiv ntawm cracking phaj.

●Polyimimide Board

●Epoxy Board

●Cem-3, fr-4, fr-5, hydrocarbon substrate

●Pawg Thawj Coj Multilayer

●Siab tg, txhuas-dawb thiab halogen-dawb, nruab nrab tg

●Qhov Kub Kub Coefficiession Resistance

| Kev sib faib | Ib yam | Qhov toob kas | Txoj kev xeem | |||||

| Nominal tuab | Um | 12 | 18 | 35 | 70 | 105 | IPC-4562A | |

| Thaj chaw hnyav | g / m² | 107 ± 5 | 153 ± 7 | 285 ± 10 | 585 ± 20 | 870 ± 30 | IPC-TM-650 2.2.12.2 | |

| Kev coj dawb huv | % | ≥99.8 | IPC-TM-650 2.3.15 | |||||

| kev ntxhib | Ci iab sab (RA) | ս m | I≤0.43 | I≤0.43 | I≤0.43 | I≤0.43 | I≤0.43 | IPC-TM-650 2.3.17 |

| Matte sab (rz) | um | Theyim | ≤8 | 150 Cov Ntaub Ntawv | ≤15 | 5Y20 | ||

| Lub zog tensile | RT (23 ° C) | MPa | ≥207 | ≥207 | ≥276 | ≥276 | ≥276 | IPC-TM-650 2.4.18 |

| Ht (180 ° C) | ≥33 | ≥33 | ≥138 | ≥138 | ≥138 | |||

| Elongation | RT (23 ° C) | % | ≥2 | ≥2 | ≥3 | ≥3 | ≥4 | IPC-TM-650 2.4.18 |

|

| Ht (180 ° C) | ≥2 | ≥2 | ≥2 | ≥3 | ≥3 | ||

| Rqhov tseem ceeb | Ω.g / m² | I≤0.17 | I≤0.166 | I≤0.16 | I≤0.162 | I≤0.162 | IPC-TM-650 2.5.14 | |

| Tev lub zog (FR-4) | N / hli | ≥0.9 | ≥1.1 | 4 | ≥2.0 | ≥2.0 | IPC-TM-650 2.4.8 | |

|

| tus lbs/in | ≥.1 | ≥6.3 | ≥8.0 | ≥11 | ≥11 | ||

| Pinholes & Porosos | Tus nab npawj | No | IPC-TM-650 2.1.2 | |||||

| Los tiv thaiv-oxidization | RT (23 ° C) |

| 180 |

| ||||

| RT (200 ° C) |

| 40 |

| |||||

Txheem dav, 1295 (± 1) hli, thaj tsam dav: 200-1340mm. Thov raws li cov neeg siv khoom thov txiav.

Peb sim cov tev lub zog nrog Fr-4 (TG140) expreg, thov tshaj tawm koj lub pp.